What do I need a safety storage cabinet for?

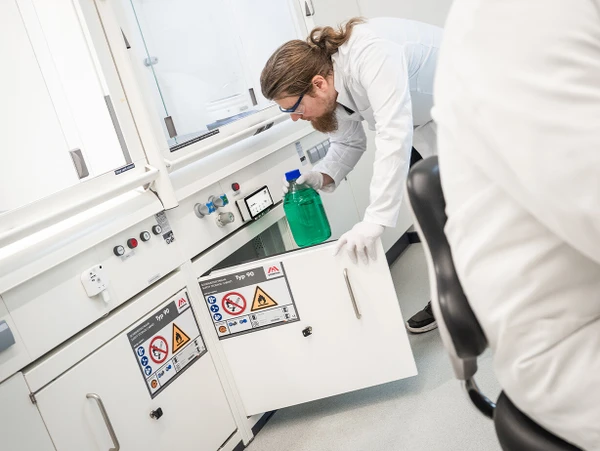

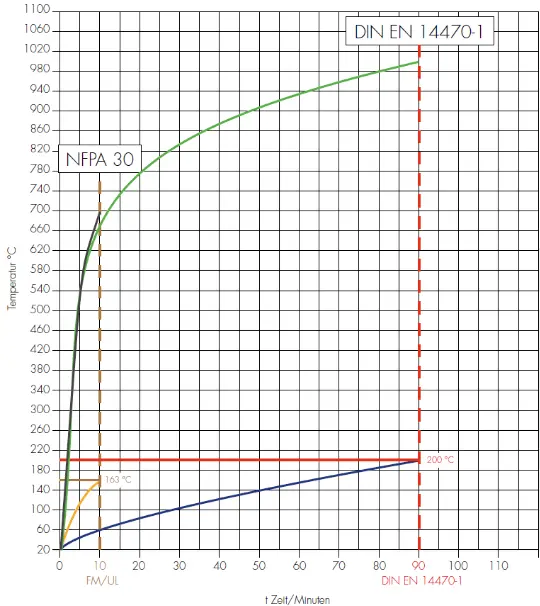

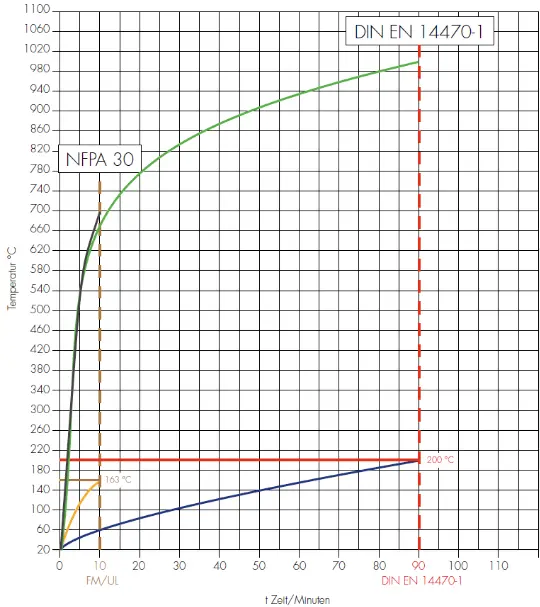

When handling hazardous substances, the utmost care is essential. Our technology with maximum fire resistance helps you achieve this. Thanks to their special design, our safety storage cabinets guarantee 90 minutes of fire resistance, type-tested in compliance with DIN EN 14470-1. In the event of a fire, DÜPERTHAL safety storage cabinets with a Type 90 fire resistance rating allow sufficient time for workers to leave the room and allow fire fighters enough time to access the laboratory. All before the flammable substances stored there enable a small, extinguishable fire to become an uncontrollable inferno. The cabinet is tested under fire conditions as standard. Each cabinet model is type-tested in a fire chamber in accordance with DIN EN 14470-1.

The fire starts

- The fire alarm is activated

- Evacuation of personal starts

5 - 10 minutes after the fire starts

- The employees are outside the danger zone

- The fire service is on its way to the site

10 - 15 minutes after the fire starts

- The fire service is at the source of the fire

- Safety storage cabinets with a fire resistance of only 10 minutes stop working at this point

- The flammable substances are no longer safely stored

- The fire service must fight the fire with a considerably increased risk

- Increased damage can be expected

90 minutes after the fire starts

Your advantages with the 90-minute technology

- Type 90 safety storage cabinets continue to function for 90 minutes

- The critical hazardous substances are stored safely for at least 90 minutes

- The fire service has considerably more time to extinguish the fire safely

- Reduction of the fire load and minimisation of damage