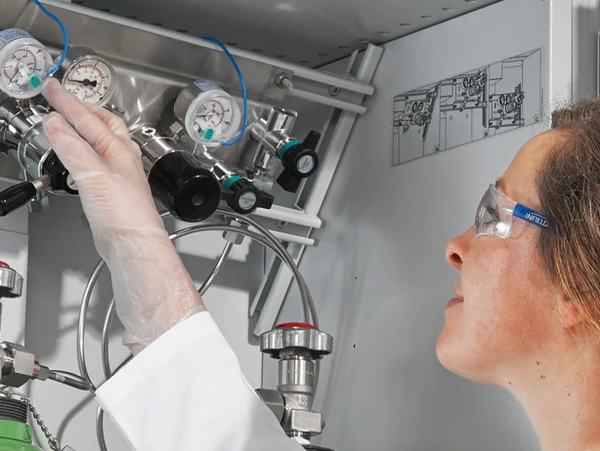

Safe storage of compressed gas cylinders

Uniform fire protection concept

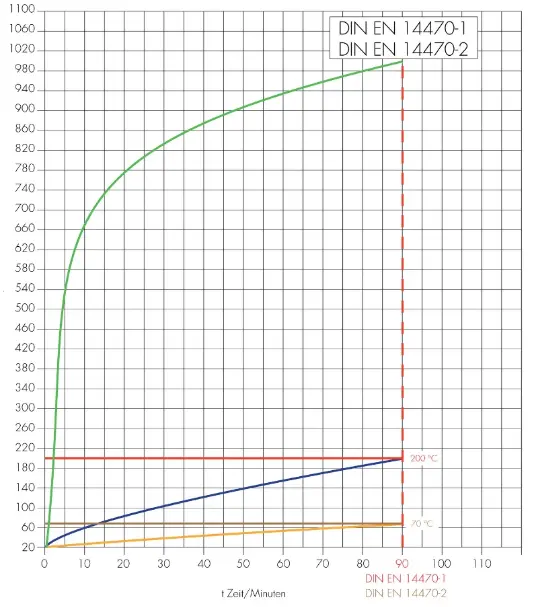

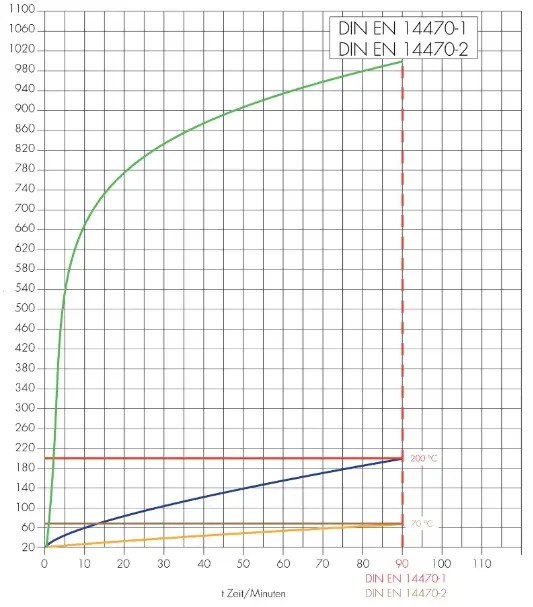

The SUPREME line safety cabinets for compressed gas cylinders help you give your laboratory continuous fire resistance throughout 90 minutes. In combination with Type 90 DÜPERTHAL safety storage cabinets – compliant with DIN EN 14470-1 – the SUPREME line is the right solution for an end-to-end fire protection concept in accordance with the highest standards.