Maximum safety and process optimisation for efficient handling of hazardous substances.

Storage of hazardous substances

with maximum safety

Safe, reliable and future-proof

DÜPERTHAL is your leading partner providing customised system solutions for hazardous substance storage. With more than 50 years of experience, we offer innovative, certified products which fulfil the highest safety standards and comply with the legal requirements. Our intelligent safety systems, such as DÜPERTHAL connect, enable digital monitoring and centralised control in real time – maximising efficiency and minimising risk.

Hear from our satisfied customers

Find out how our partners benefit from our customised system solutions for hazardous substance storage. Their opinions demonstrate why DÜPERTHAL stands for safety, efficiency and innovation.

Our

awards and prizes

DÜPERTHAL has won and been nominated for numerous prizes for its outstanding products and services. Our technologies set the benchmark for the industry, as proven by our nominations and awards. We are also proud to have been honoured with the "2025 Product of the Year" from LABO and other renowned prizes.

Inside DÜPERTHAL

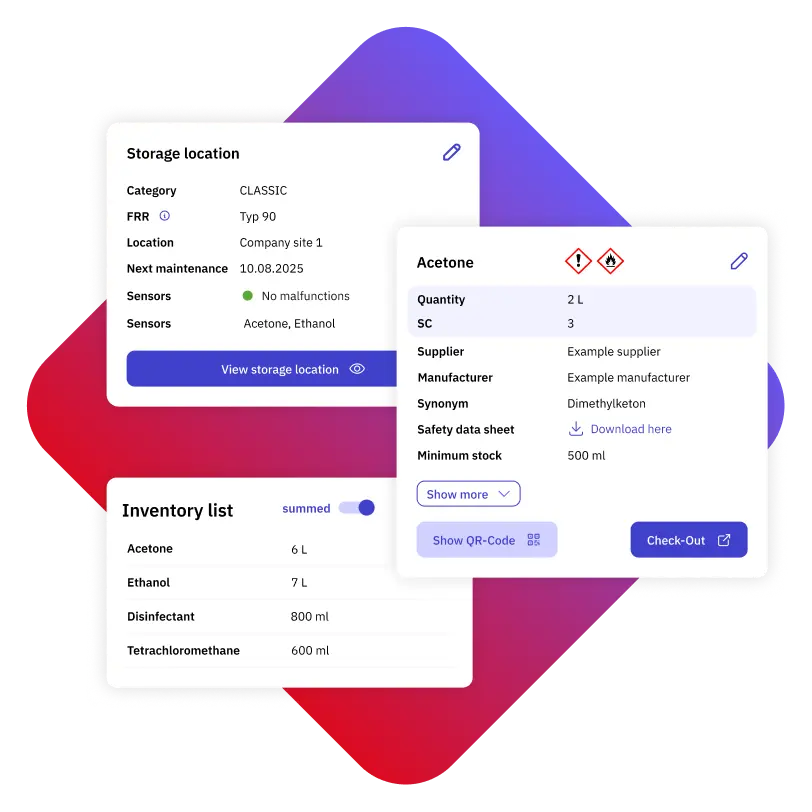

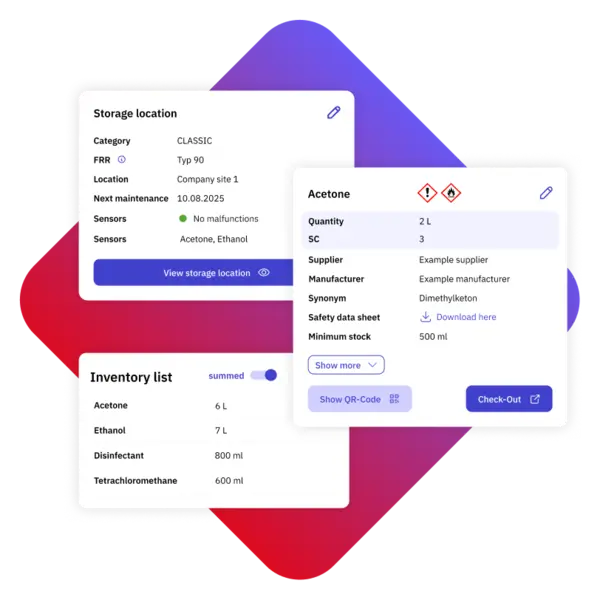

DÜPERTHAL connect – intelligent inventory management for resources with risk potential.

DÜPERTHAL connect networks your safety storage cabinets and storage locations digitally, allowing you to permanently monitor important data such as fill levels and temperatures – for increased safety and efficiency when managing hazardous substances.

Frequently asked questions

Here are the answers to some frequently asked questions about DÜPERTHAL and our products. From safety storage cabinets and maintenance, through to individual solutions – here you'll find some of the most important details at a glance. If you don't find the answer to your question, please get in touch with us so we can help you in person.

We offer you comprehensive support, from advice on selecting the right cabinet, through to professional installation and initial on-site training by our team of experts.

Yes, with retrofitting and adjustment, many of our products can be integrated seamlessly into existing systems. Contact us to find the ideal solution for your requirements.

Yes, many of our products have options for individual customisation, such as colour variants, special internal equipment or digital monitoring functions. Take a look at our safety storage cabinets and configure your cabinet!

Yes, we offer a comprehensive maintenance and repair service for all our products, including older models. This is how we ensure your systems always remain safe and work properly. For more information, please go to our Inspection and maintenance page.

About us – DÜPERTHAL Sicherheitstechnik

DÜPERTHAL is your partner for safe and innovative solutions for handling hazardous substances. With high-quality products and individual, expert advice, we ensure maximum safety and efficiency in your daily work.

Our strengths:

- Decades of expertise in the management of hazardous substances

- Individual solutions for laboratories, industry and research

- Optimum quality and compliance with all safety standards